3D additive printing is becoming more commonplace in today's industries. To improve the properties of printed polymers, a paper published onchemxrivhas explored the incorporation of aramid nanofibers (ANFs) into printable photoresins.

Study:立体光刻的3D印刷Aramid纳米纤维复合材料。图片来源:NikkyTok/Shutterstock.com

3D打印: A Revolutionary Technology

3D打印是一项革命性的技术,可创建三维对象一层。3D打印技术已用于在国际空间站的汽车行业制造医疗设备,甚至被用来打印整个房屋。

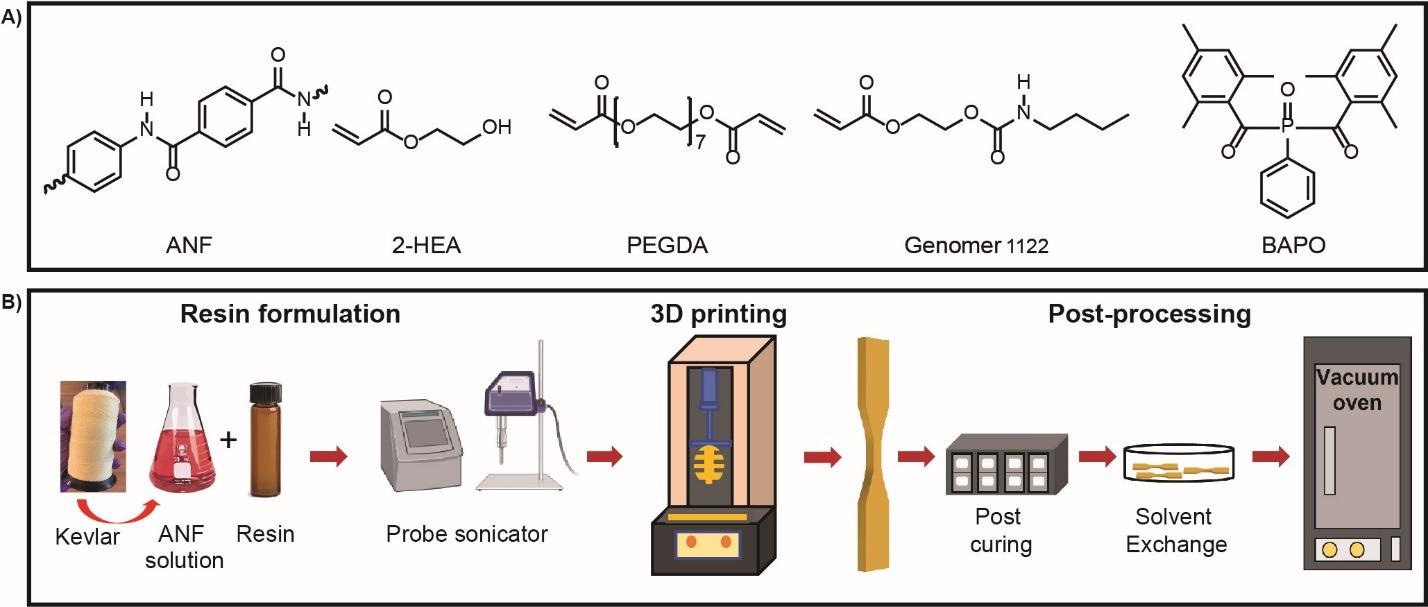

(a)用于配方含有光蛋白的成分的分子结构。(b)本研究中印刷纳米复合材料的纳米填充剂制备,照明和后处理程序的步骤的示意图。图片来源:Perera,S等人,ChemXriv

3D printing produces highly complex, customized structures cheaper than conventional mold-based fabrication methods, and produces less waste than traditional manufacturing. Additionally, 3D printing can take advantage of a plethora of materials to create commercially useful products. Much focus has been placed on improving both the technology and the properties of materials used for 3D printing.

增值税聚合和立体光刻学

Recently, there has been increasing attention on vat polymerization printing methods in the 3D manufacturing field. This is due to their high fabrication speeds and resolution. Stereolithography is a vat polymerization process that uses a laser to achieve photopolymerization of a photoinitiator containing acrylate-based resins.

立体光刻可以产生光滑完成的高质量物体,分辨率小至10微米。该技术需要光蛋白,这些光蛋白含有液态状态的单或低聚物,该液态可以在暴露于光线时快速聚合并且必须具有低粘度。目前,该技术的树脂选择受到限制,因为许多当前面临的制造挑战,因此所得的印刷结构的机械和热性能不足。

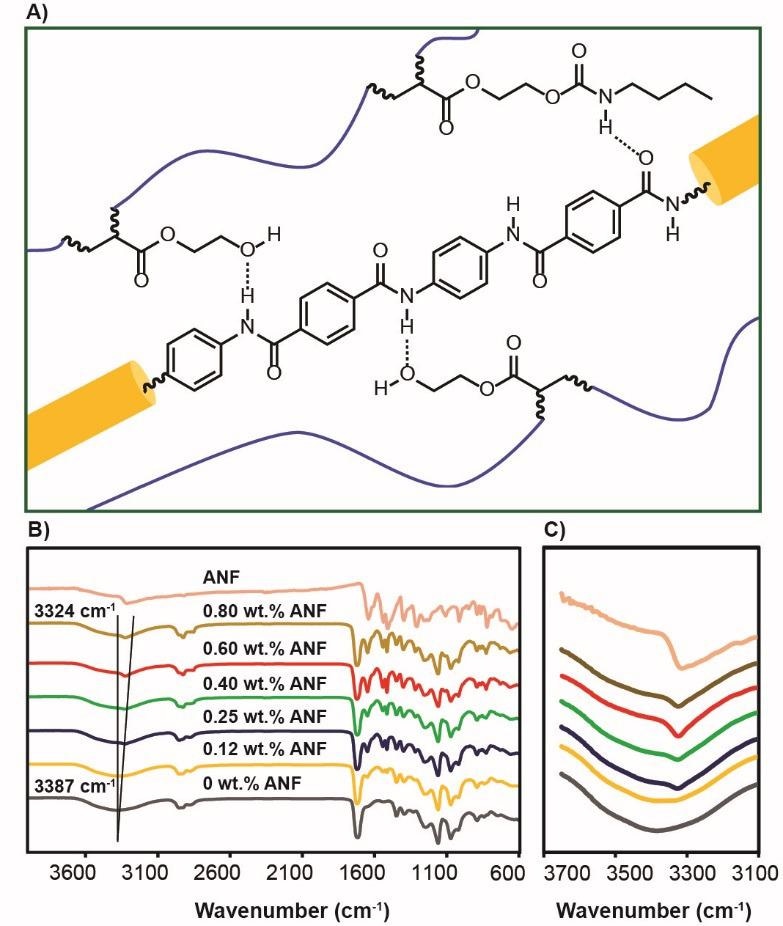

(a)ANFS(AM-IDE组)和光蛋白(羟基)之间的氢键形成。(b)3D打印后具有不同浓度的ANF的对照光片蛋白和纳米复合材料的FT-IR光谱。(c)3D打印后,对照光蛋白和纳米复合材料的膨胀羟基拉伸区域和纳米复合材料具有不同浓度的ANF。图片来源:Perera,S等人,ChemXriv

Improving Photoresins for Stereolithography

对具有更好性能的光蛋白的迫切需求可以产生可行的3D印刷结构。为此,已经探索了复合材料和纳米复合材料。复合材料是有利的,因为可以低成本将不同的添加剂与聚合物矩阵混合,并且该过程也可扩展。亚博网站下载可以产生具有一系列吸引人特性的材料。

Nanofillers such as carbon nanotubes and cellulose nanocrystals have been explored as they improve the mechanical, electrical, and thermal properties of composite materials. Even though the field has produced numerous polymeric nanocomposites, the application of these in 3D printing, and especially in vat polymerization methods, is still limited.

在立体光刻印刷中使用芳族纳米纤维

发表的研究背后的团队chemxriv开发了一种开发含有含有光蛋白的芳族纳米纤维的过程,这些光蛋白可以使用立体光刻印刷。

由Kevlar纤维组成的Aramid纳米纤维一直是最近研究的主题。这些纳米复合材料由于其强分子间相互作用而亚博网站下载表现出出色的强度和刚度。即使在聚合物基质中包括少量这些纤维也会提高机械性能,例如韧性和拉伸强度。

Additionally, aramid nanofibers can be used in applications such as water purification, biomedical technologies, and products that require advanced infrared absorption. However, these materials are still not commonly used in 3D printing. Reasons for this include the difficulties of incorporating them into printable, homogenous mixtures of resins.

克服阿拉米纳米纤维的问题

如前所述,使用这些纳米复合材料的主要问题之一是难以制造包括它们在内的同质光蛋白。为了克服这个问题,使用二甲基亚氧化二甲基亚氧化物在溶液中添加了芳香纳米纤维。

Another issue is the quality of printed structures. To avoid the induction of defects such as cracks and produce parts that retain their resolution and shape, the team developed an optimized post-print processing method.

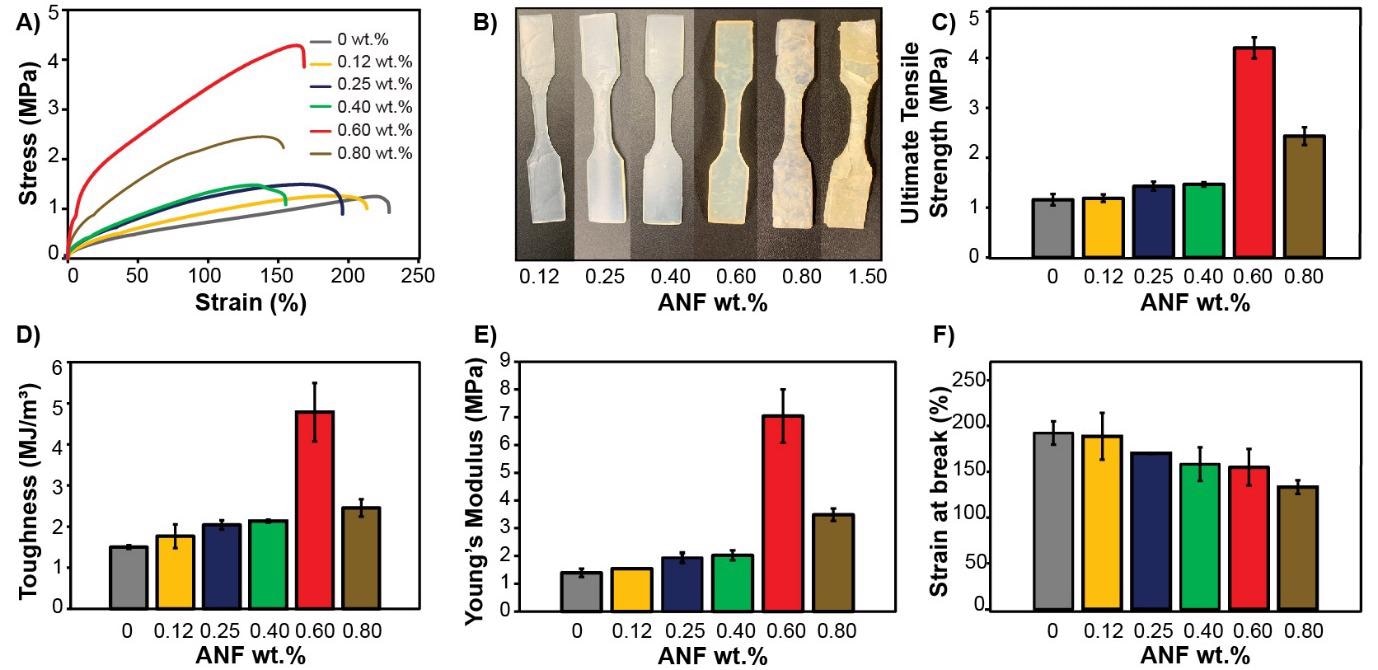

所得的印刷产品由于将芳香纳米纤维纳入聚合物基质而显示出升高的拉伸强度和韧性,尽管在一定浓度的可打印材料中观察到了一定浓度的Aramid纳米纤维载荷,但在可打印的材料中观察到了降低的机械性能。研究表明,芳香纳米纤维是有吸引力的添加剂,可以使用光蛋白在不损害其可打印性的情况下为结构提供纳米尺度的增强。

评估对照光蛋白和ANF纳米复合材料的机械性能。(a)具有不同浓度ANF的纳米复合材料的SLA打印的拉伸标本。(b)代表性应力 - 应变曲线。(c)最终的拉伸强度。(d)韧性。(e)杨的模量。(f)在对照光蛋白和纳米复合材料的断裂时应变,其浓度不同。图片来源:Perera,S等人,ChemXriv

未来

随着行业利用其收益来生产具有出色的机械和电气性能的材料,其成本较低且更可持续的材料,3D打印领域正迅速变得越来越普遍。亚博网站下载通过开发包括纳米复合材料在内的新技术和高级材料,在3D印刷领域工作的科学家正在建立该亚博网站下载行业的未来。

The research paper has demonstrated the potential of aramid nanofibers and their use in stereolithography printing to produce commercially viable materials in a scalable manner. The team has identified a few challenges that still need to be addressed, however. They have stated that their future work in this area will be developing new resin composites that have higher aramid nanofiber loading, using the post-print processing methodology set out in the research.

免责声明

Important Notice: ChemRxiv publishes preliminary scientific reports that are not peer-reviewed and, therefore, should not be regarded as conclusive or treated as established information.

进一步阅读

Perera,s等。(2021)立体光刻的3D印刷Aramid纳米纤维复合材料[online] chemxriv.org. Available at:https://chemrxiv.org/engage/chemrxiv/article-details/618B13682BF8A9ADF5D6510C

免责声明:此处表达的观点是以其私人身份表达的作者的观点,不一定代表AZOM.com的观点有限的T/A Azonetwork本网站的所有者和运营商。此免责声明构成了条款和条件使用此网站。